How To Do Repair A Bearing

How To Do Repair A Bearing

July 30, 2019 Comments Off on How To Do Repair A BearingAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss;

Bearing Repair

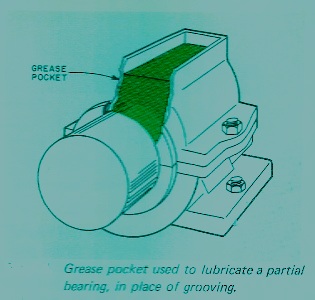

You can repair a damaged bearing by refurbishing its inside surface. The process depends on the bearing itself. The surface of the solid or partial bearings can be machined smooth and the lubricant grooves re-cut. The lined split type bearings can be redone by just relining the bearing. The thin insert type is just thrown away and replace with a new one.

If you want to re groove a bearing , use a round nosed tool and go by the original groove pattern. The depth of the groove shouldn’t be be more than one- third the wall thickness of the bearing. Making sure not to round or bevel the edges of the groove after re-cutting. Grease grooves are wider and deeper than oil grooves, but you apply the same principle.

If you need more information on this topic, please leave us a comment.

Or call us at 800-361-0068

hydrostaticpumprepair.com