Hydraulic Rebuild Process

Hydraulic Rebuild Process

November 9, 2016 Comments Off on Hydraulic Rebuild Process

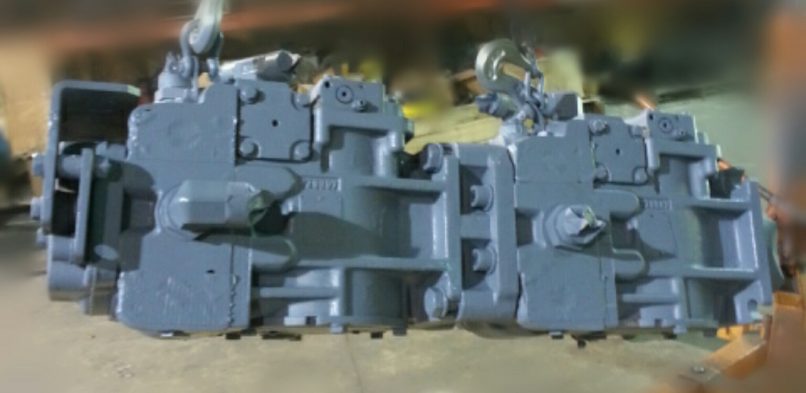

Rebuild Process

- Each unit is pressure washed, disassembled, and inspected by trained technicians.

- Each part is cleaned using a solvent and placed in a reduced – dust environment.

- All working parts are checked, measured, and calibrated to manufacturer specifications.

- All displacement valves and bypass valves are disassembled and rebuilt or replaced.

- Parts are reconditioned, machined, or replaced to meet manufacturer specifications.

- High pressure manifold rebuilt and inspected.

- Charge pump rebuilt to specification.

- New gaskets, O-rings, and seals replaced (Including new shaft seal)

- The unit is checked for leaks using a testing apparatus.

- Quality Charts are recorded and checked against specifications.

- Pressure and flow adjustments are made to specifications.

- Unit is then filled with oil to prevent condensation during shipping.

- Unit receives fresh paint job and quality seal.

If there is further information needed, please let us know.

800-361-0068

sales@hydrostatic-transmission.com