Pneumatic & Automatic Valves

Pneumatic & Automatic Valves

September 1, 2023 Comments Off on Pneumatic & Automatic Valves

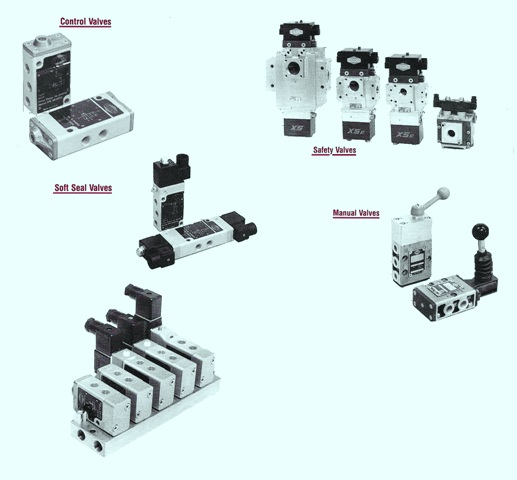

Safety Valves – this valve is a dual valve made to give comparable flow formation. There are three different kinds of these valve: XSE – which is a type of monitoring that lets pneumatic pressure balancing that has an electrical interlock. Next you have XS – the monitoring on this has non contacting sensors that helps with wear and tear on the sensor when you adjust it. Lastly, XSZ – a new type valve has a type of monitoring system that doesn’t have moving parts.

Manual Valves – S2/3 have a linear hand motion lever that has a rotary actuated lever. One of it’s applications is a lapped spool design that lets a low actuation and a general port connection, spring return, detent style and panel mounting.

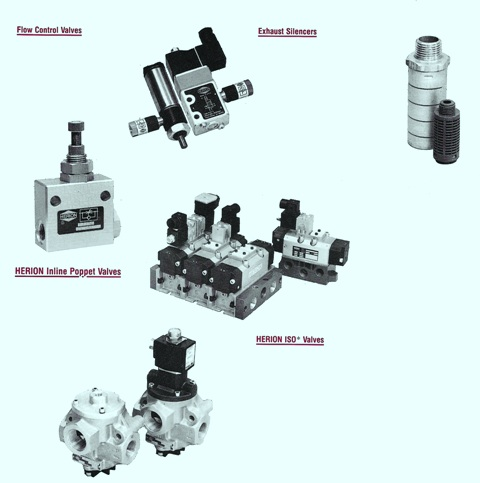

Poppet Valves – this is a three way, two placement solenoid & air working poppet valves in port sizes from 1/2 to two npt that gives you a quick response time that repeats really quickly. The poppet lets you have a better flow routine.

Exhaust Silencers – that give noise dilution while giving you low back pressure. The general sizes are 1/8 to an inch in order to offer noise cancellation for the pneumatic valve or air tools to work.

ISO Valves – a new feature that will let a 2/3 way to be mounted interchangeable with different amounts of ports and placements.

Most of these have a T ring sealing arrangement to give better shifting. It offers fast response time, vacuum is at 240 psi., bubble tight sealing, solenoids have low current depletion and working with/without greasing it.

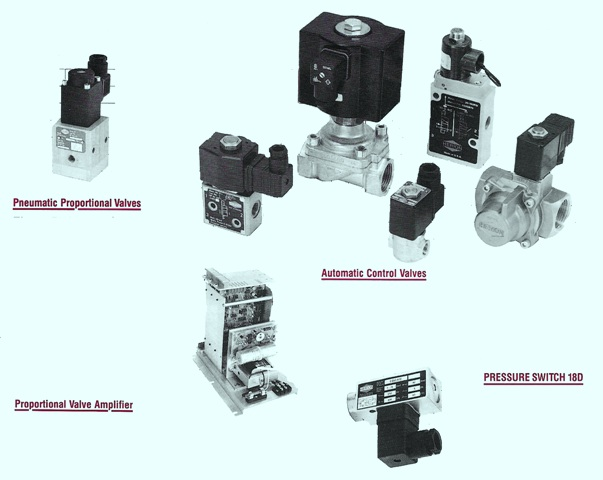

Proportional Valve Amplifier – this gives an electronic link to using it alot in micro computers for pneumatic control units. The PVA is make to switch modes in the controller to drive the valve. The amplifier gives an output current that is equal to the input voltage instructions.. It also may incorporate a ramp control along with adjustments to the front panel. Pressure Switch ISO – this is small, reliable and doesn’t cost much to run on hydraulic/pneumatic units to put it on. Switching pressure – 1-400 bar, working temp – 25 degrees C to 80 degrees C., 15g of vibrations force and switching rate of100cpm.

Automatic Control Valve – these valves are made to work with water, air, oil and other fluids and some gases also. They can be put on 2/3 way and long list of sizes. It has a piston seal with a diaphragm valve. You can get it in

If you need more info on these valves, call us at 800-361-0068

sales@htsrepair.com