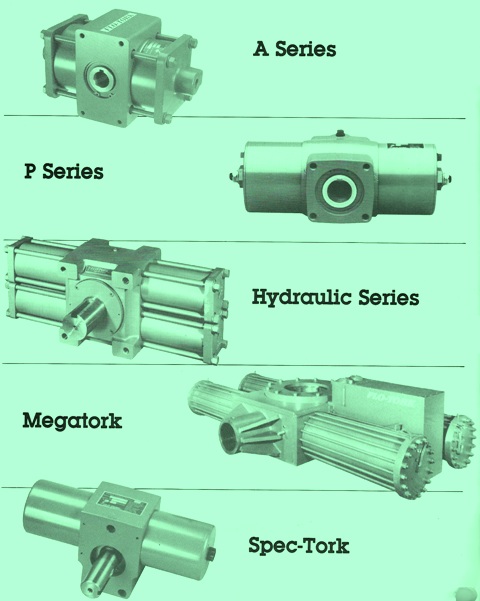

Rotary Actuators A-100/500/1000 Series Part One

Rotary Actuators A-100/500/1000 Series Part One

February 14, 2023 Comments Off on Rotary Actuators A-100/500/1000 Series Part One

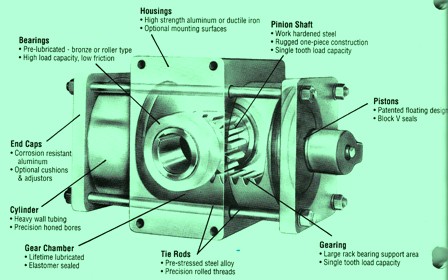

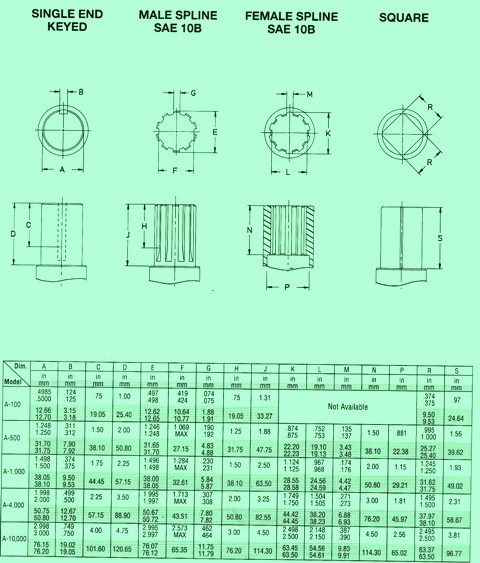

Features Extra’s you can get on it

125 PSI max pressure changeable cushions

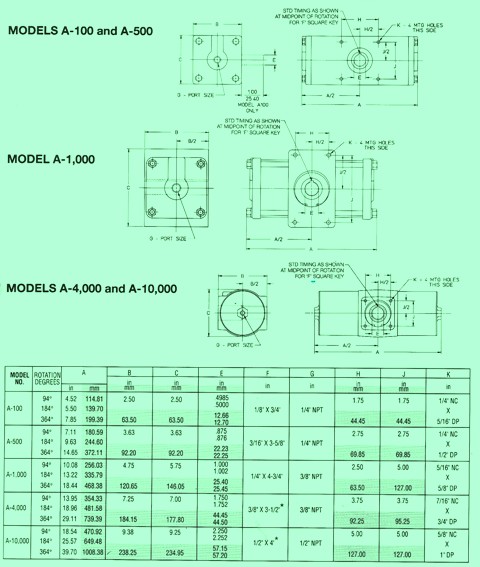

100- 10000 lb in at 100 psi – torque stroke adjustors

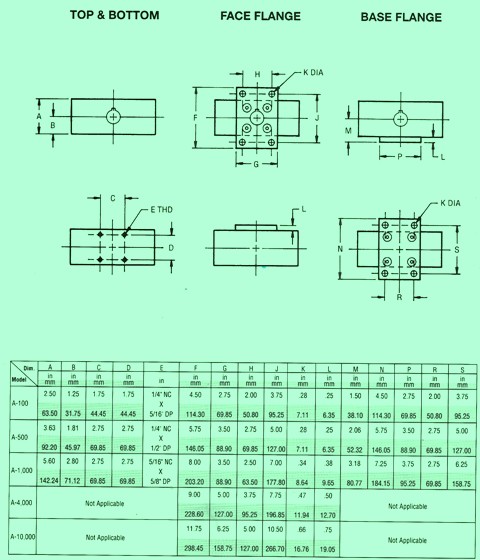

rotation 94, 184, 364 degrees ports are o ring SAE or NPT

rack and pinion – mechanical performance side or end ports

no leakage – high volume different mounting options

accurate bearings- heavy duty load range with very little friction different shafts

piston seals- block v customized rotations

gearing – single tooth and standard load range customized sealing

temp range – 40 – 250 degree F. different coatings

Housing – A to 100/500 aluminum hard coated

Cylinder ID ends are by left side is number 1 and the right side in number 2 when you look at the front face when the keyway is at 12:00 and the actuator is a in the middle of rotation. The ports for the air rotary come the usual way and some can come customized.

If you need more info on this unit, call us at 800-361-0068

sales@htsrepair.com

About the author:

Susan RichardsonCategories

- 4 way valve (23)

- air driven liquid pumps (32)

- air operated valves (10)

- air switch (25)

- bearings (189)

- caterpillar (183)

- caterpillar (193)

- cessna (190)

- charge pump (6)

- compensator control (181)

- couplings (36)

- cranes (192)

- cylinder (175)

- cylinders (190)

- denison (60)

- DMIC FLUID POWER (37)

- dynapower (69)

- eaton (204)

- edc control (8)

- excavator (190)

- Gresen motors (40)

- Gresen pumps (39)

- Hall Model 33 Blower (35)

- hall pump valve (30)

- haskel (32)

- HDC cnotrol (8)

- heavy equipment (190)

- hitachi (142)

- hydraulic (182)

- hydraulic (181)

- hydraulic parts (189)

- hydraulic quick couplings and interchangeable (34)

- hydrostatic (181)

- hydrostatic parts (189)

- Hydrostatic Transmission (804)

- industrial (189)

- john deere (142)

- kawasaki (189)

- komatsu (189)

- linde (141)

- load sensing (41)

- load sensing control (177)

- lubrication (184)

- machinery (188)

- mdc control (8)

- MGG2 Motors (40)

- mini pressure relief valve (12)

- mitsubishi (141)

- Nicholas HTLS (49)

- oil cooler (47)

- parker (60)

- PGG2 Pumps (40)

- pressure compensated thrust plates (34)

- pressure differential adjustment (176)

- quick exhaust valves (22)

- rexroth (141)

- series 33 Hall Blowers (35)

- series 40 m46 pump (7)

- series 40 n46 HDC (9)

- series 8 haskel air/gas boosters (33)

- Series A heat exchanger (26)

- series h101 pump valve (29)

- Series K heat exchanger (26)

- series PGG2 hydraulic pump (39)

- Series UR Parker Control Valves (14)

- solenoid 2/3 way valve (24)

- solenoid cartridge valve (31)

- solenoid pilot control valve (10)

- sundstrand (188)

- sundstrand sauer danfoss (193)

- ultra power drive pump and motor (28)

- ultra power line pump and motor (29)

- vickers (187)