John Deere 755B Crawler – Remove and Install Oil Pan

John Deere 755B Crawler – Remove and Install Oil Pan

April 6, 2018 Comments Off on John Deere 755B Crawler – Remove and Install Oil PanAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic

Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss;

John Deere 755B Crawler – Remove and Install Oil Pan

- Take out front bottom guard.

- Let the engine oil out. Capacity is about 20 qts.

- Take out the dipstick and tube.

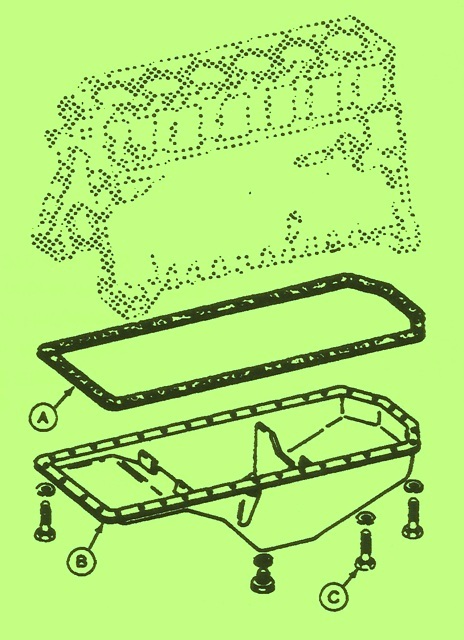

- Take out the cap screws (C) & washers to let out the oil pan (B).

- Administer the form in place gasket to joints between the timing gear cover, front plate, cylinder block & flywheel housing to fill in between end of gaskets & oil pan gaskets.

- Pun in a new gasket (A).

- Put in the oil pan. Make sure to tighten oil pan to timing gear cover cap screws to (27 lb-ft) and tighten oil pan to block cap screws to (35 lb-ft).

- Put in new o rings on dipstick tube. Then put the tube and dipstick.

Also try not to tighten the cap screws to tight that go to the oil pan to timing gear cover.

If you need more info on this subject, please leave a comment.

Or you can call 800-361-0068

Email: sales@hydrostatic-transmission.com

Tags:

755B backhoe block cap blogs combine cores crawler dipstick drive ebay store equipment excavator exchange facebook flywheel housing gasket hydraulic hydrostatic instagram john deere machinery motor oil pan orings pinterest pump rebuild reman repair replace shopify surplus timing gear cover cap screws tractor transmission twitter video youtube