Bearing Selection For What Application

March 20, 2018

At our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss:

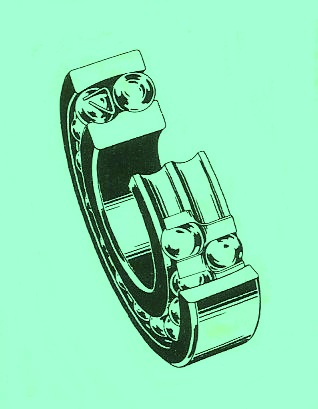

Bearing Selection

Bearing means support for a rotating shaft or spindle (small shaft). It also can mean support or guide for one component of a piece of equipment which slides across another. Almost all mechanisms have one or both types of unit or surface that require some kind of bearing.

Bearing selections depends on the application itself. Such factors to consider which bearing to use is the horsepower required at the working point of the equipment to get the job done. Basically, you have to choose the right bearing for each job to give the best performance out of the equipment at the precise time between the source of power and work delivery point.

Here are some factors to consider

1. Equipment purpose and type

2. Horsepower needed

3. Required bearing life

4. Equipment location (indoor, outdoor, corrosive surroundings)

5. Load (the amount of weight or pressure which the bearing must support)

6. Type of load (axial, radial, combination)

7. Shafts

8. Tolerances

9. Design of equipment (location of bearing in equipment)

10. Shaft speed (RPM)

11. Operating temperature

12. Lubrication

There may be other factors, but these are the most important ones to figure.

If you have questions or like to leave a comment, we would be most welcome to your joining in on our discussion.

Call 800-361-0068

email: sale@hydrostatic-transmission.com