Sundstrand Sauer Danfoss Series 20 Circuits & Characteristics

Sundstrand Sauer Danfoss Series 20 Circuits & Characteristics

June 23, 2017 Comments Off on Sundstrand Sauer Danfoss Series 20 Circuits & CharacteristicsSundstrand Sauer Danfoss Series 20 Circuits & Characteristics Of a Pump/Motor

In our discussion today we will talk about Circuits and their differences

In hydrostatic transmissions there are 4 components involved:

Fixed Displacement Motor

Fixed Displacement Pump

Variable Displacement Motor

Variable Displacement Motor

And these can be combined into 4 circuits

Variable Displacement Pump driving a

Variable Displacement Motor

Variable Displacement Pump driving a

Fixed Displacement Motor

Fixed Displacement Pump driving a

Variable Displacement Motor

Fixed Displacement Pump driving a

Fixed Displacement Motor

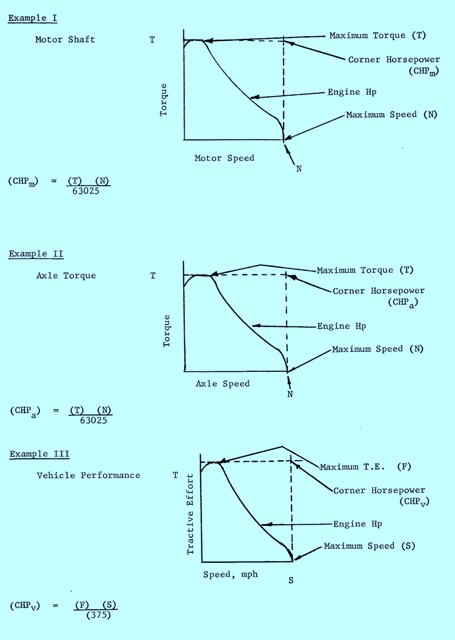

All of these circuits off different performance characteristics. In the following descriptions, the input speed is constant. When you are wanting to vary the input speed and introduce other control methods, the process of applications rapidly broadens. The horsepower at any given working pressure is directly proportional to pump flow. The torque of the motor depends on its displacement and the working pressure established.

Circuit #1

Variable Displacement Pump – Variable Displacement Motor

1. Maximum efficiency occurs near mid speed.

2. The efficiency is highest over a broad part of the speed range.

3. Output speed is controlled by both pump displacement and motor

displacement. (and input speed)

4. For optimum hydraulic sizing, the is approximately one half the size

(displacement) of the motor.

5. This circuit has the widest output speed range.

Circuit #2

Variable Displacement Pump – Fixed Displacement Motor

1. Maximum efficiency occurs near top input speed.

2. Output speed is controlled by pump displacement (and input speed).

3. For optimum hydraulic sizing, the pump size (displacement) is equal

to motor size (displacement).

4. This is the simplest system providing infinite control.

It is the most frequently used system.

Circuit #3

Fixed Displacement Pump – Fixed Displacement Motor

This combination is the hydraulic equivalent of a mechanical shaft and gear drive. It can be used to transmit power without altering the speed of horsepower between the engine and the load. This transmission would be convenient if the power source is remote from the load.

Circuit #4

Fixed Displacement Pump – Variable Displacement Motor

With the pump driven at the constant speed, the circuit is a constant horsepower, variable speed, variable torque transmission. Output speed is controlled by changing the displacement of the motor. As motor speed increases, output torque decreases. The system has no neutral because of the fixed displacement in the pump.

The foregoing illustrates basic arrangements of hydrostatic transmissions. A simple system of one pump and one motor was used to illustrate basic circuits. It must be realized that many variations of circuits are possible. By this we mean, it is possible to use one pump with two motors–two pumps and two motors, etc…It is also common practice to use different sizes of pumps and motor in combinations. Regardless of the pumps and motors use, the basic characteristics apply.

To know more about this topic or any that we discuss on the blog…let us know by calling 800-361-0068 or emailing us at info@hydrostatic-transmision.com

hydrostaticpumprepair.com

sales@hydrostatic-transmission.com