Vickers Single Vane Pump Repair

Vickers Single Vane Pump Repair

June 14, 2018 Comments Off on Vickers Single Vane Pump RepairAt our Hydrostatic Pump Repair Site, we offer many types of Hydrostatic Transmission Repair and information relating to Hydrostatic Parts

Today we will discuss;

Vickers Single Vane Pump Repair

| Flood all parts with system fluid at assembly to offer initial greasing.Put “O” rings into inlet body and vanes into rotor with radius edge of both vanes outward. Place rotor and vanes on inlet body. Mount ring over rotor and vanes with arrow or ring pointing in direction of rotary motion. Then add the two alignment pins through ring into inlet body. Put pressure plate over ring with alignment pins situated in pinholes of pressure plate. The pressure plate must be flush against the ring at the completion of this step. (Flood all parts of cartridge with system fluid). Place springs over the main pressure plate then fit in the “O” ring then into the cover. Adjust cover to line up with prick punch marks and thread screws through cover and ring into inlet body. Torque screws to 35-45 lbs ft. (47.5-61 n.m.). Mount “O”ring over the chief part of inlet body and set the competed vane pump aside and cover the port opening to avoid entry of dirt or other contamination |

| DISASSEMBLY OF PISTON PUMP TURNING GROUP AND VALVE BLOCK |

| Use recommended torque “E-12 to undo six screws from the housing and valve block.Set aside gasket, then slide opened roller bearing from the end of shaft.

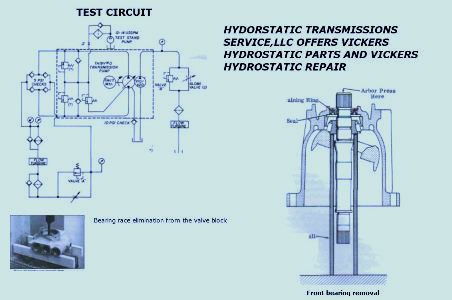

Put the wafer plate from valve block the put the pin from valve block, and then slide bearing spacer off shaft. Take out the rotary motion group parts throughout as a whole unit. Hold the shoe plate piston and she sub assemblies and cylinder block with both hands to prevent separation of the turning group during removal. Take out parts (44 thru 47) from cylinder block as instructed. Warning The spring positioned within the cylinder block is under high spring tension and might cause injury if retaining ring is removed without great caution. Disassemble valve block as instructed: Label both valves to allow reassemble into the same bore opening. Check valves expand a wear pattern within the valve block and my leak of the valve is interchanged. Take away the two plugs “O” rings springs and cross line replenishing check valves or from valve block. A small tubular magnet is useful in the process. Make a Note Of Some types of parts use a mixture of cross line release and check valve assemblies in place of replenishing checks. The blend of release and check valves are not repairable. Put back the complete assembly if found flawed. Next remove two locating pins if defective, but be careful not to mar the face of the valve block during taking out the part. Examine the bearing for score marks or brineling of the rollers. If the shaft bearing is not perfect, remove the bearing race from the valve block. Use proper tools for removal of parts. DISASSEMBLY OF YOKE PARTS AND REMOVAL OF THE FRONT SHAFT BEARING AND SHAFT

|